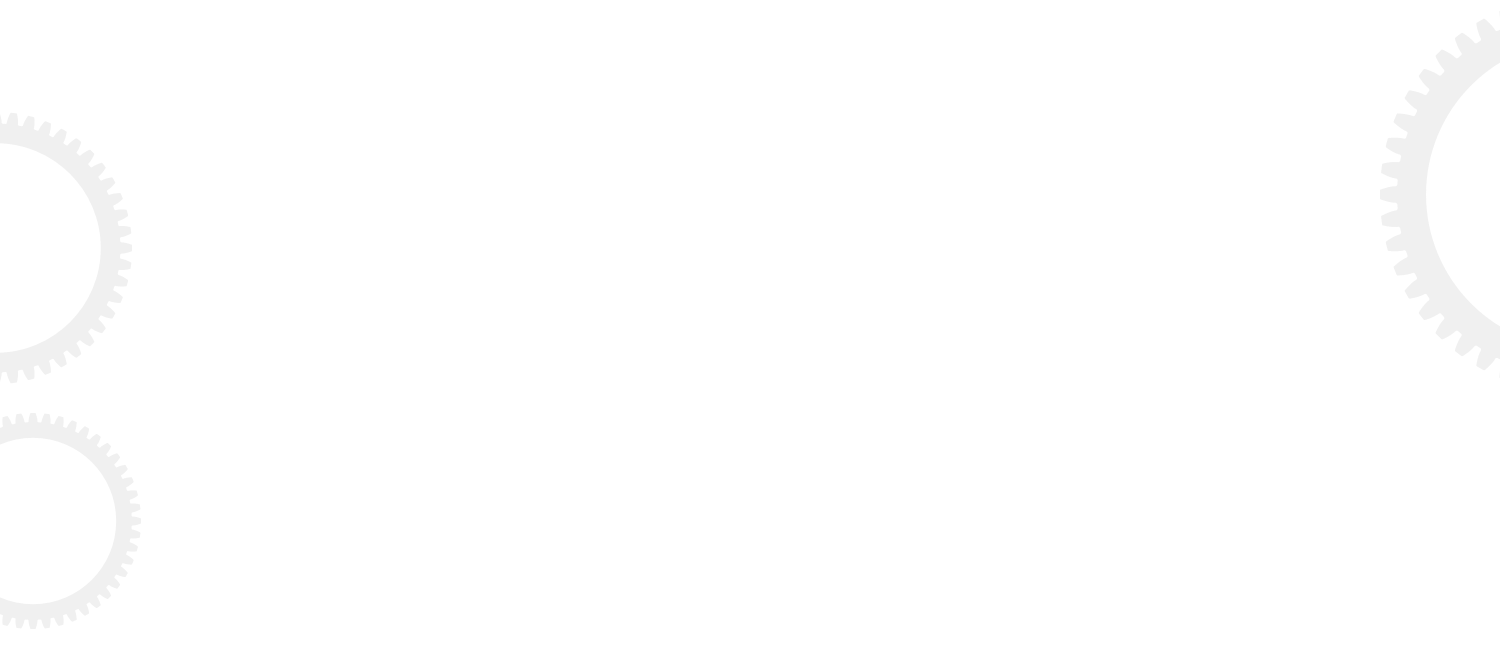

Scout Loader

Scout Loader is a fully automated feeder designed to directly offload deadpacked lumber fr…

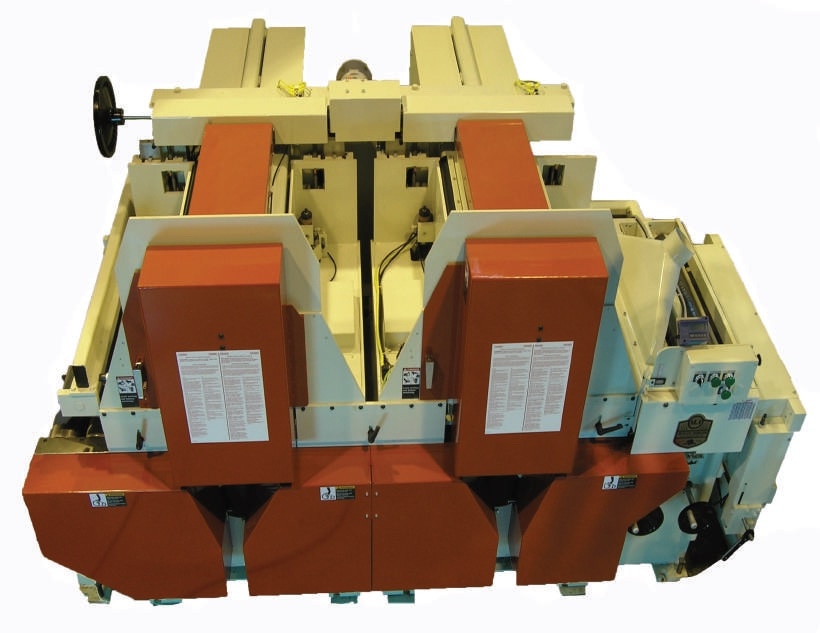

Our Roll Feed Saw’s high-speed, high-yield hogging arbor options virtually eliminates edgings. With these machines, you’re guaranteed to increase production & improve yield management by selecting a Mereen-Johnson Roll Feed Rip Saw tailored just for you.

Improve Profits by Virtually Eliminating Edging

Our Roll Feed Saw’s high-speed, high-yield hogging arbor options virtually eliminates edgings. With these machines, you’re guaranteed to increase production & improve yield management by selecting a Mereen-Johnson Roll Feed Rip Saw tailored just for you.

Through our advanced technology, we’ve virtually eliminated edgings, improved profits, & operator safety with the following:

Our Market-leading technology & state-of-the-art construction will result in the lowest cost-of-ownership, improved accuracy, detailed production, and vendor reporting. All of which is backed by the best warranty on the market and a specialized Parts & Service Department capable of answering any question that may arise.

Robust steel tube and plate construction maximizes performance, increases longevity and reduces maintenance requirements.

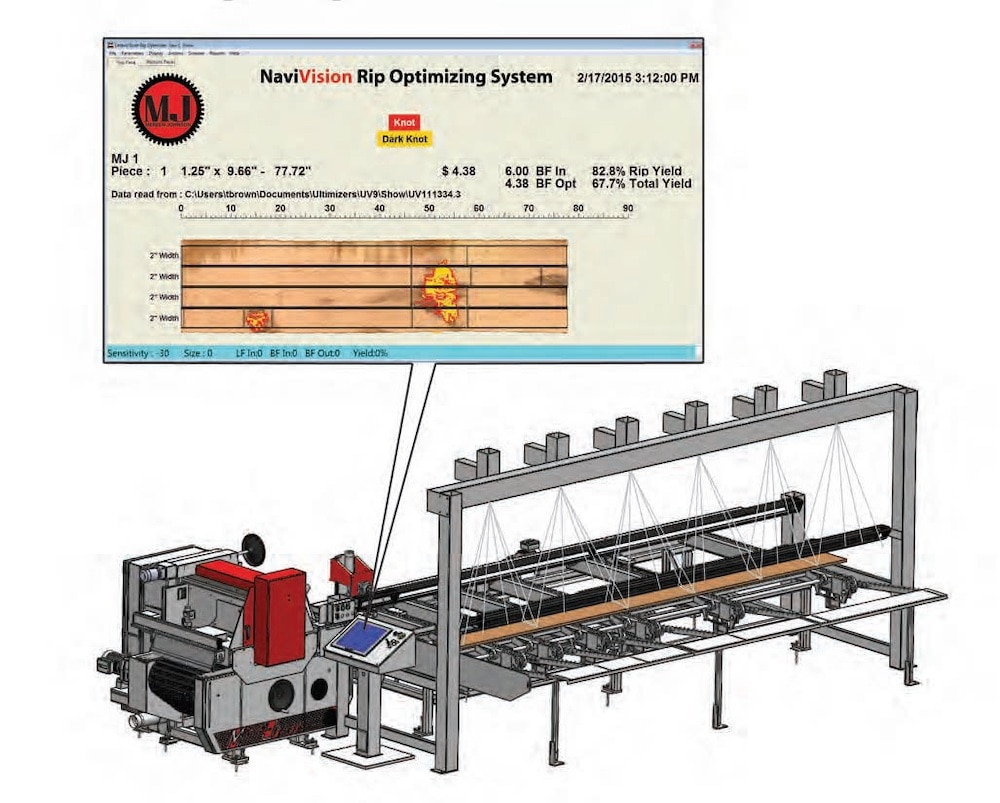

Operator intervention station with servo controlled lasers integrated to Rip Navigator controls allow operators to see the computer generated solution and if required, edit.

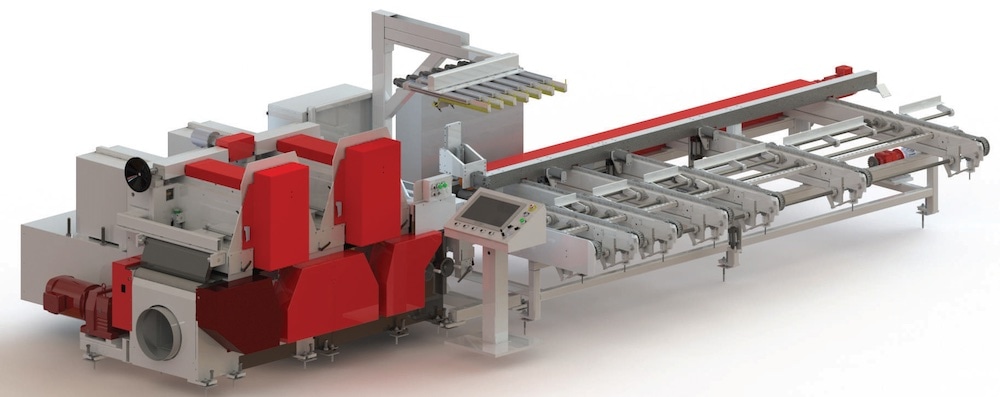

System guide is mounted on linear ways for smooth and accurate positioning integrated with Rip Navigator control. Integral upper and lower rolls both jump for accuracy and reduced wear.

Accumulator arms with integrated board dealer allows a single operator to control the system.

Mereen-Johnson Power Tables feature dual rolls with pressure compensated drive and timing features for accurate feeding and minimal saw feed bed wear.

The Model 524-RF/SR Roll Feed Select-a-Rip Saw, when combined with the high speed Rip Navigator Scout-HS, will provide better feeding accuracy, detailed production and vendor reporting, improved lumber yield, higher pro?its and greater operator safety.

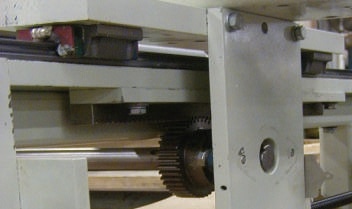

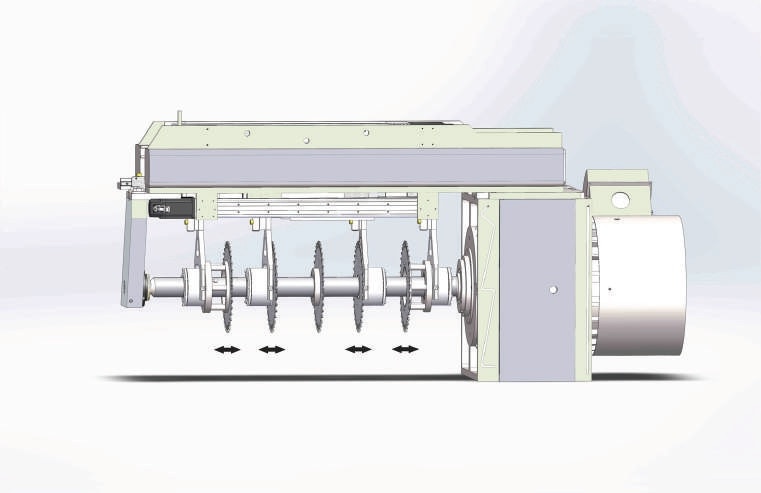

| Capacity | 24” arbor space. |

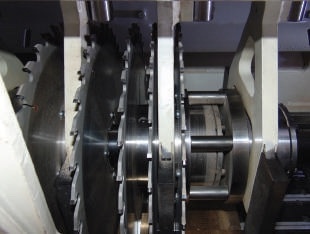

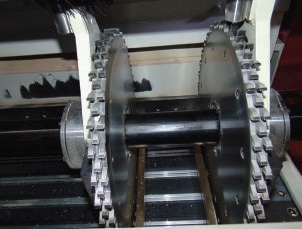

| Shifting Saw(s) | First arbor; Two shifting hoggers (optional). Second arbor: One to four shifting blade(s) in combination with optional fixed center blade. 1″ min. width net rip between saws. |

| Arbor Drive | Belt Drive up to 150 HP, 3600 RPM TEFC saw arbor motor. |

| Feed Rate | Up to 500’ per minute. |

| Hold Downs | Eight 4” dia. air loaded press rolls with optional hogging arbor. Infeed and outfeed air loaded shoe hold downs. |

| Dust Collection | One 18” dia. and one 5” dia. upper – 9,680 total CFM required. |

| Electrical | Arranged for 3/60/230 or 460 volt power supply (other electrics available). |

| Shipping Information | Nominal 13’ by 6’ by 6’ shipping skid, 14,400 lbs, 6,550 kg. |

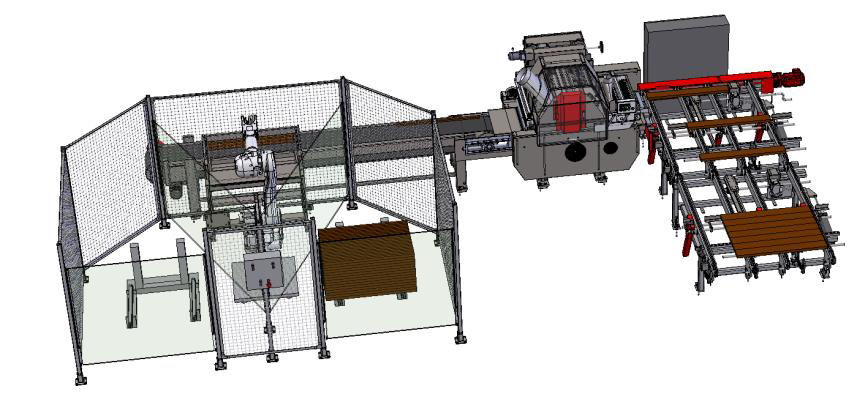

Automation & Robotics

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

Vertically integrated manufacturing in the USA means we control every step of the process to deliver the performance and longevity that the industry has grown to expect from us.

Listening to your specific needs, we will adapt a standard machine or develop a fully custom solution, including automation and robotics, and manufacture it in-house.

Our state-of-the-art production space has room to build, test and prove large-scale design solutions. Design-build teams work together to make your custom concept a reality.

We will always support your machine. From training programs to replacement parts, schematics to software support, we’ve got you covered, remotely or onsite.

Scout Loader is a fully automated feeder designed to directly offload deadpacked lumber fr…

Our largest Rip Optimization system is the Scout; Equipped with infeed chains, board deale…

Now with NaviVision scanning, Mereen-Johnson provides multiple color cameras for single fa…

Mereen-Johnson manufacturers a complete line of gang rip saw infeed systems from manual to…

With up to four moving saw blades, Select-Ripping has never been more affordable. Our 500…

Mereen-Johnson Multiple Rip Saws offer straight line precision gang ripping with glue join…

The Mereen-Johnson 300 Series rip saws offer all the quality, heavy-duty construction, and…

For big shop performance at a small shop price. 12″ arbor capacity with up to two inboard…

The Diehl Machines MR-90 is an undercutting roll feed gang rip saw. The roll feed design r…

Diehl’s Full-Sized Rip Saw, a machine with the speed and performance to meet the most dema…

The Diehl Machines SL-35 is are our mid-sized Rip Saw, an economically priced machine with…