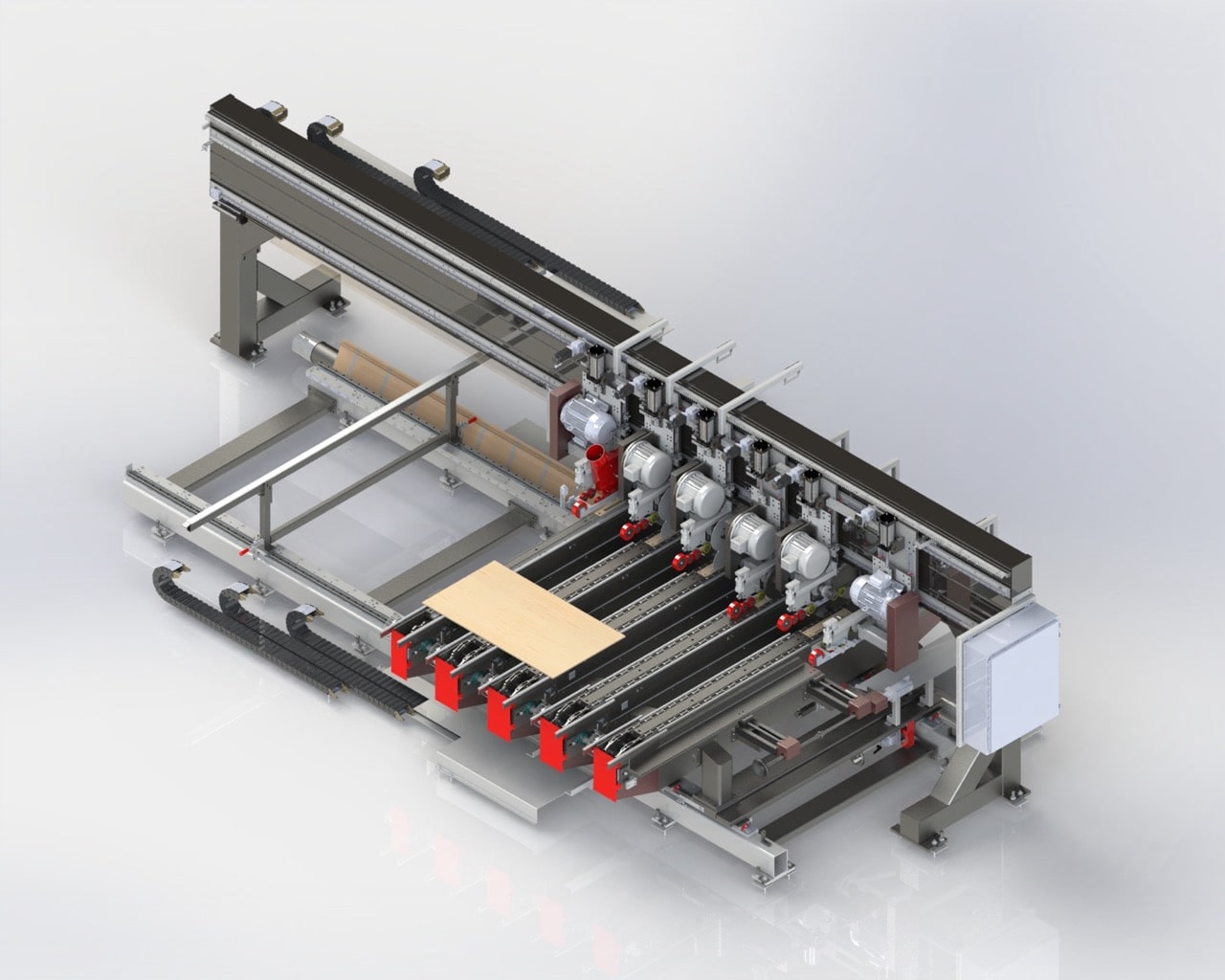

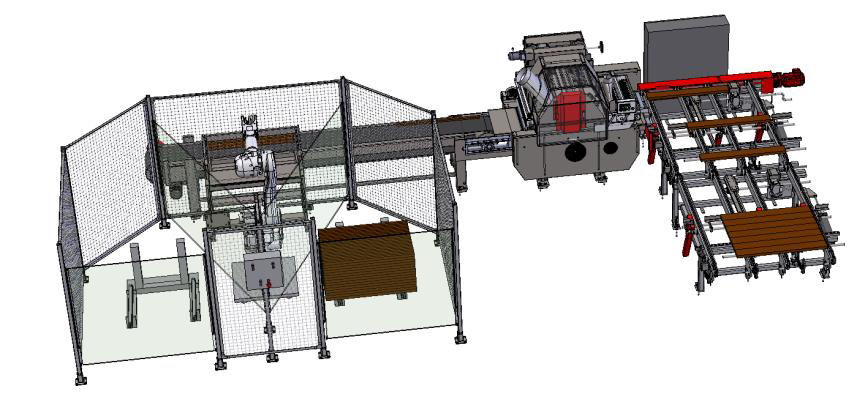

435 Panel Saw

Model 435 Series is a versatile line of machinery custom designed and manufactured for nea…

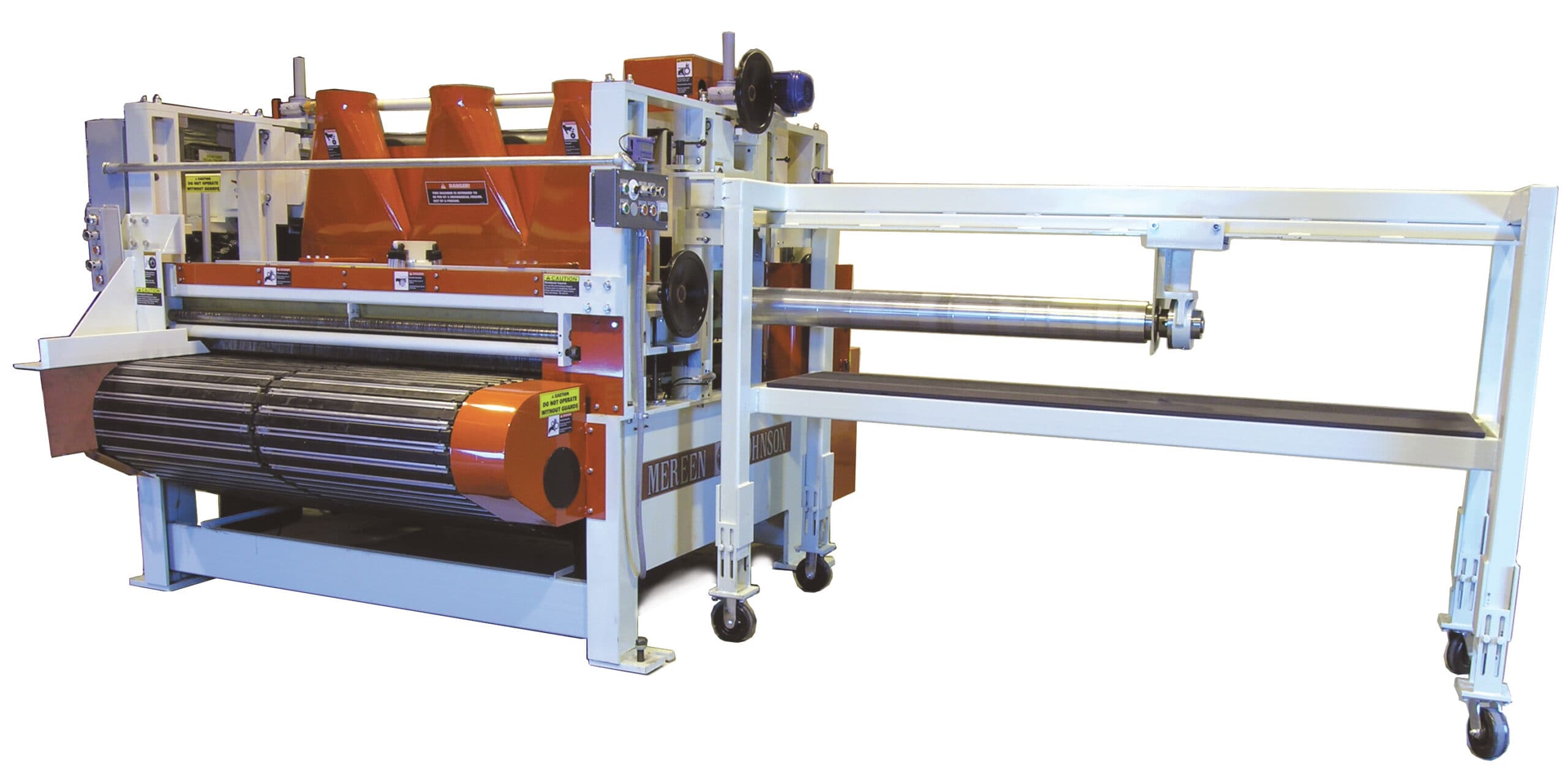

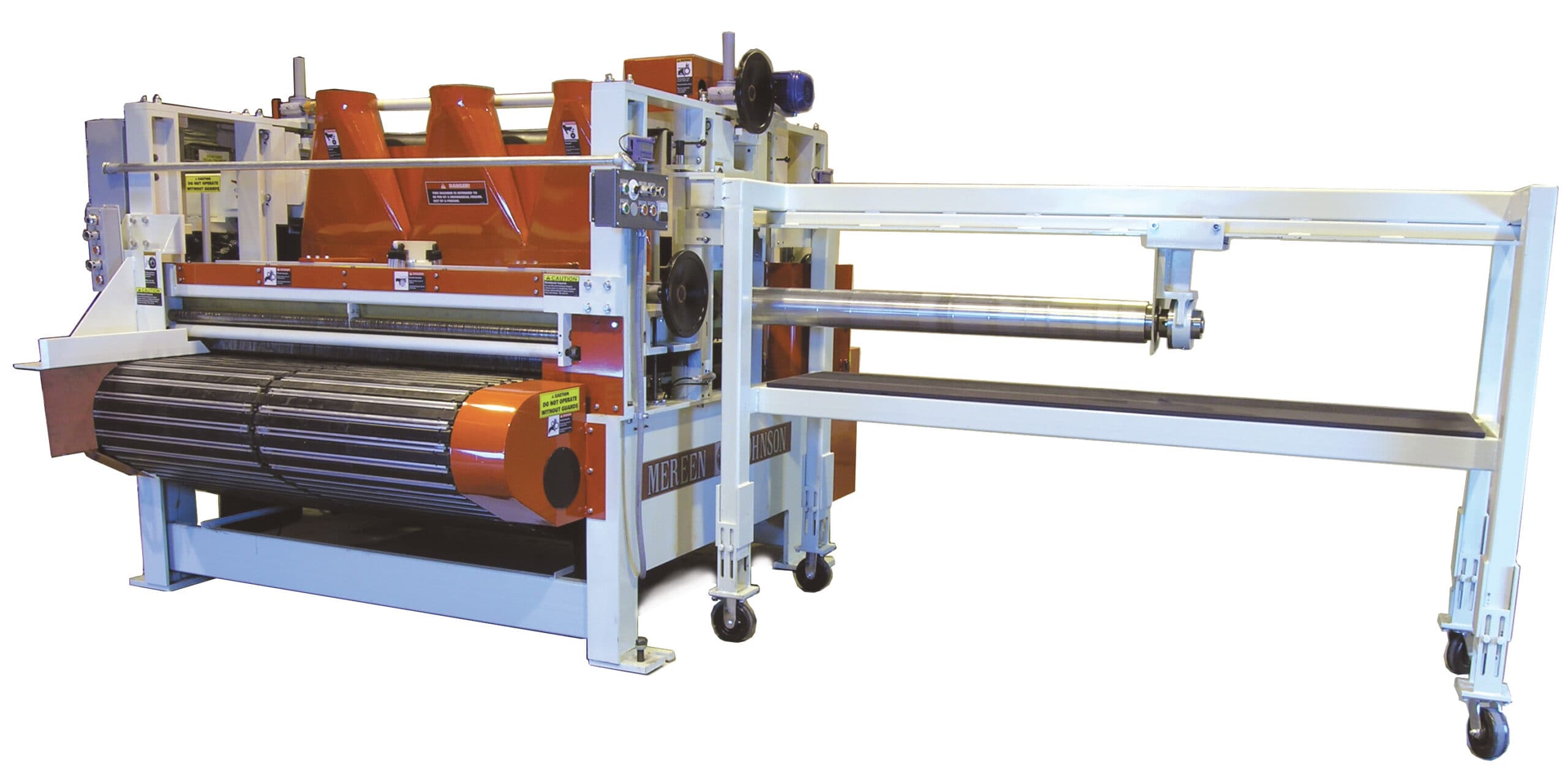

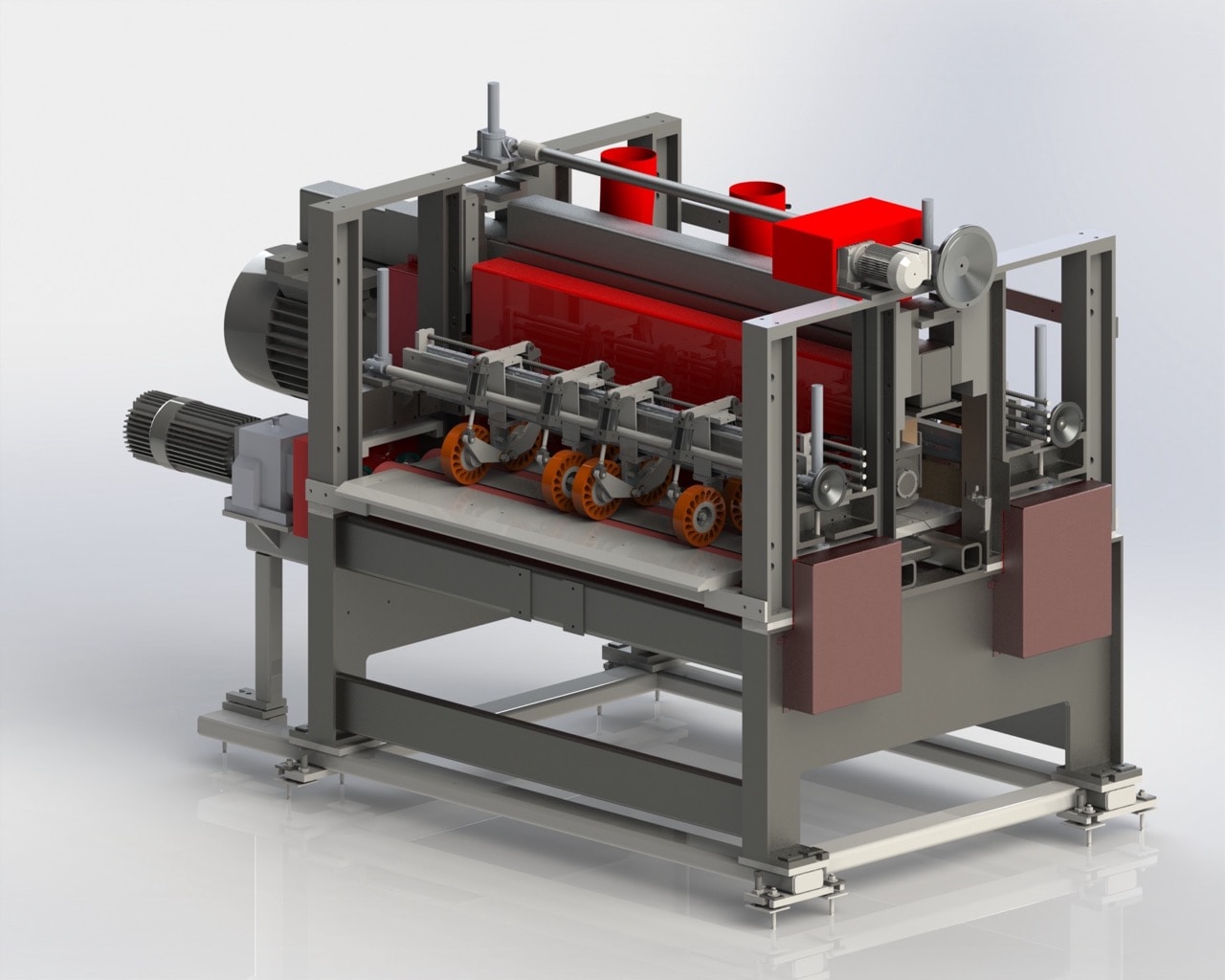

Mereen-Johnson’s wood sizing machines are engineered to deliver high precision in wood, laminate, and engineered product sizing. Whether you are processing LVL, plywood, hardboard, OSB, particleboard, or other materials, our wood processing machinery is built to handle even the toughest tasks. Designed to improve efficiency and reduce waste, our systems ensure the highest yield and profitability from your raw materials.

From door sizing machines capable of handling up to 5,000 doors per shift to panel sizing machines designed for high-volume, three-shift production, our solutions are perfect for businesses looking to optimize their operations. Mereen-Johnson is a trusted leader in wood processing machinery manufacturing, providing industry-leading durability, reliability, and performance.

Key Benefits of Our Sizing Machinery:

Machines

Model 435 Series is a versatile line of machinery custom designed and manufactured for nea…

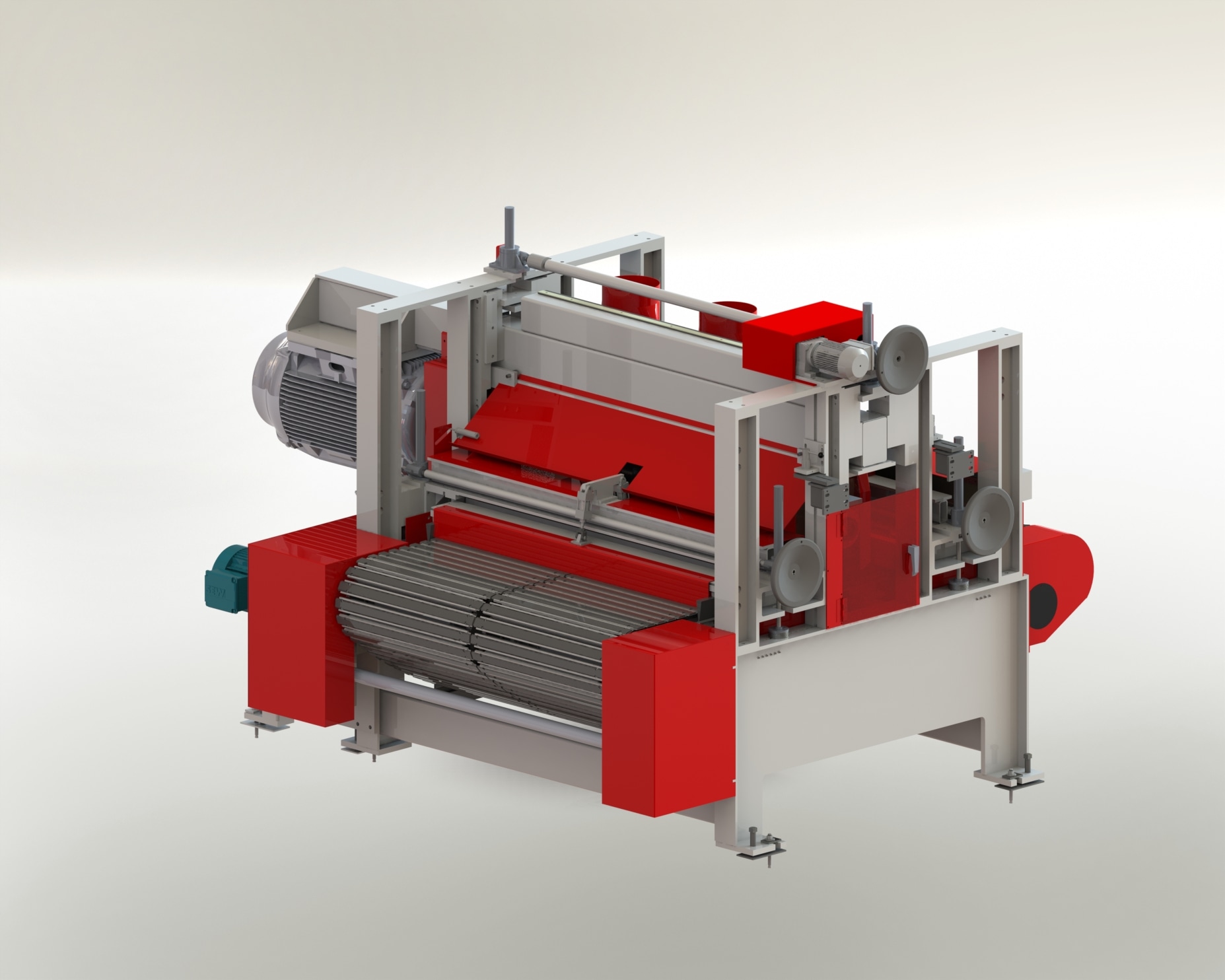

Our Tenoners are designed for high production runs while simultaneously providing the flex…

Feature the latest in technology advancements, ensuring improved consistency, accuracy, su…

Our state-of-the-art door sizing solutions can give you the ability to size as many as 5,000 doors in a single shift. Learn more about our door sizing systems.

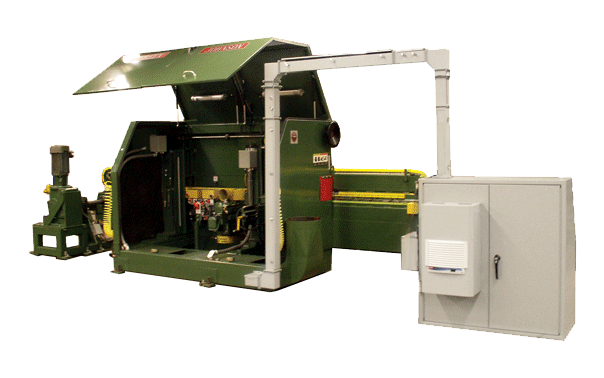

Our sizing machine capabilities include ceiling tile production equipment with advanced technology and Mereen-Johnson’s legendary durability. With installations worldwide, we are a leading manufacturer of ceiling tile production equipment.

For customers producing custom manufactured panels, our panel sizing machines are robustly constructed for three-shift production performance. Options include multiple arbor machines for ripping, chamfering and dado grooving in a single pass.

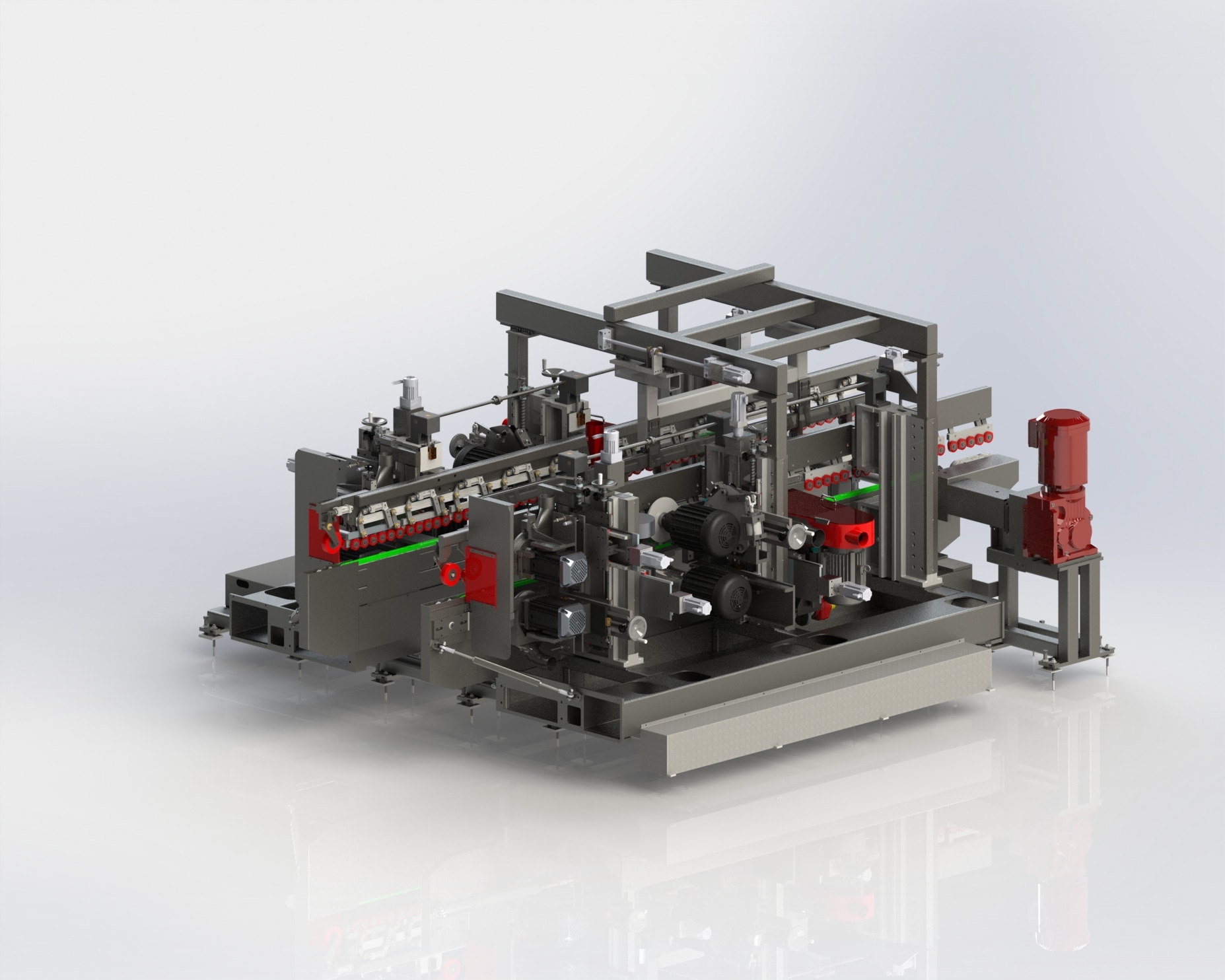

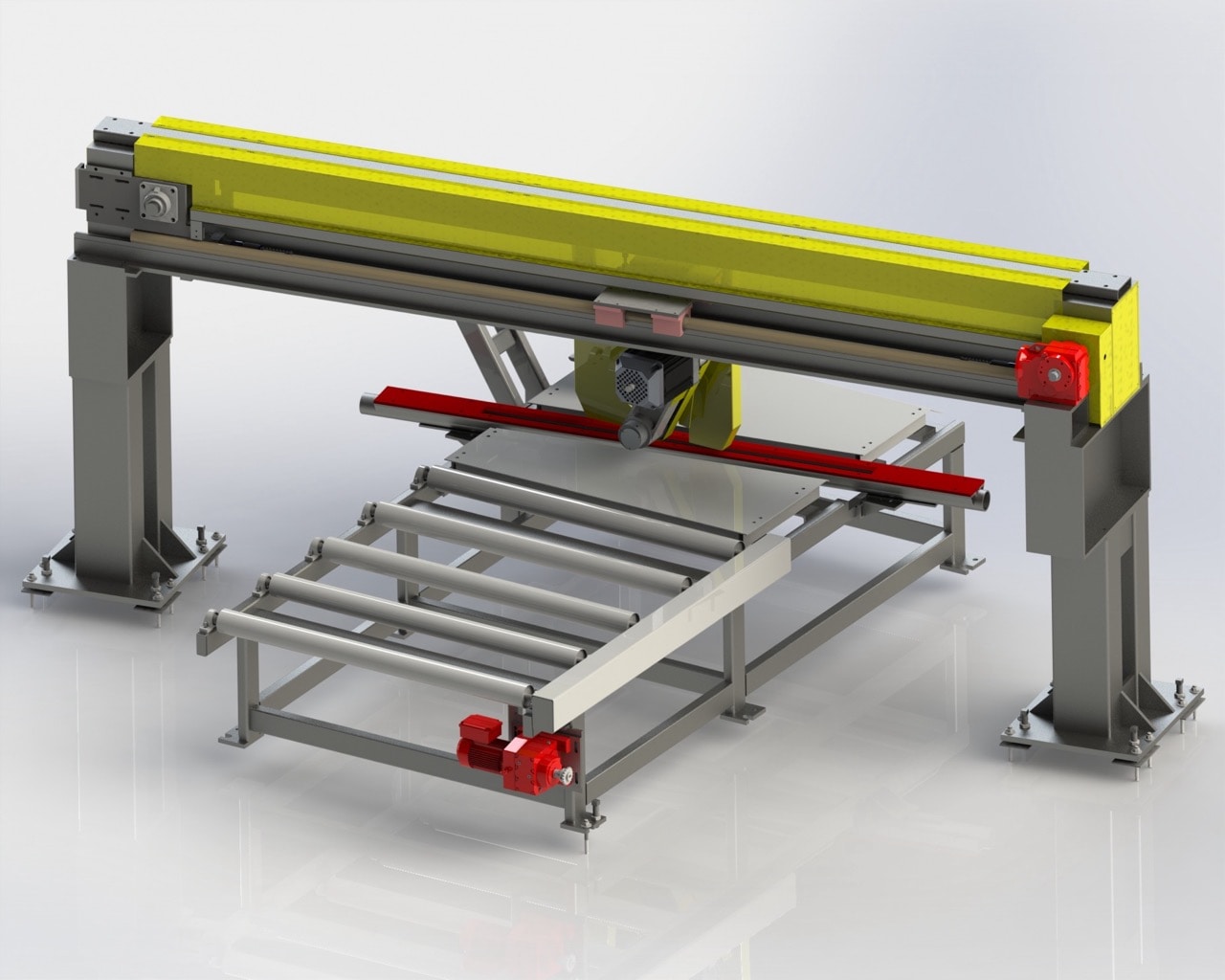

Automation & Robotics

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

Mereen-Johnson’s sizing machinery is designed for a wide variety of applications. Whether you are producing custom panels, ceiling tiles, or doors, our machines offer high performance and reliability, making them an ideal choice for businesses looking to streamline their production processes.

Mereen-Johnson’s sizing machines are built to optimize your production line. Whether you need high-speed panel sizing machines for custom orders or door sizing solutions for large production runs, our machines provide the precision, reliability, and automation integration that enhance your operations. With minimal downtime, easy-to-use interfaces, and high-performance cutting, Mereen-Johnson ensures your business maximizes efficiency and profitability.

Our sizing machines are designed to optimize material usage by providing precise, accurate cuts that reduce scrap and increase overall yield, helping businesses save on material costs.

Yes, our wood processing machinery is designed to work with a variety of materials, including softwood, hardwood, laminate, and engineered products such as plywood, OSB, and particleboard.

Mereen-Johnson’s sizing machines can be seamlessly integrated into your existing production workflow. We offer custom solutions tailored to fit your production needs, whether you need infeed systems or automatic transfers.

Our sizing machines are built for durability and minimal maintenance. Routine inspections and cleanings will help maintain optimal performance and extend the lifespan of the equipment.

Our door sizing machines are designed to handle high-volume operations, capable of sizing up to 5,000 doors per shift. With intuitive controls and high-speed performance, they help reduce setup time and maximize production throughput.