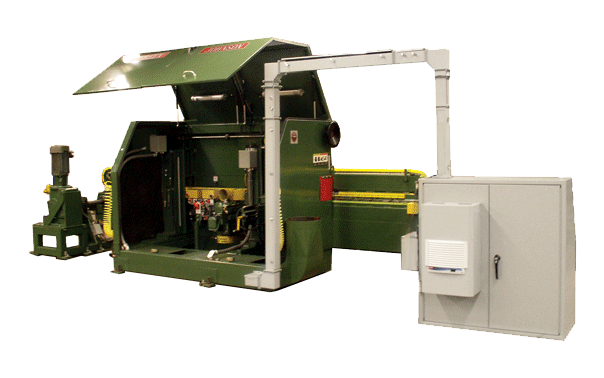

Single End Tenoner

Our Tenoners are designed for high production runs while simultaneously providing the flex…

Feature the latest in technology advancements, ensuring improved consistency, accuracy, superior joint, & quality of finish.

Whether you have a single-function or a multi-station application design, the Double-End Tenoner is constructed to accommodate severe-duty, multi-shift production.

Our intuitively designed state-of-the-art controls will improve your production. Durable construction also minimizes maintenance, resulting in reduced downtime & increased profits.

Our Tenoners are designed for high production runs while simultaneously providing the flexibility of variable sizes & small-batch runs. Ideal for panel raising, outer door profiling, contouring, & much more.

Whether you work with wood, composites or other green resources, Mereen-Johnson Single-End Tenoners are up for the task.

Features

Machines

Our Tenoners are designed for high production runs while simultaneously providing the flex…

Feature the latest in technology advancements, ensuring improved consistency, accuracy, su…

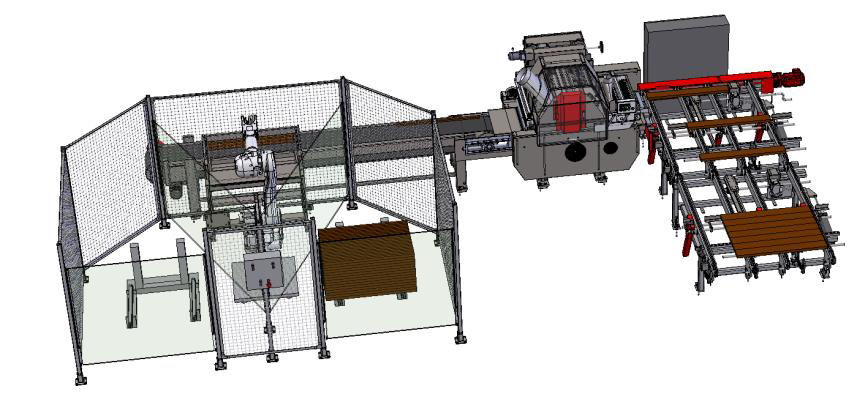

Automation & Robotics

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

Mereen-Johnson’s tenoner machines are engineered to offer the best of both worlds: flexibility for custom orders and efficiency for high-volume production. Whether you need a single end tenoner for small-batch production or a double end tenoner for large-scale operations, our machines provide the precision, durability, and performance you need. With intuitive controls, low maintenance requirements, and durable construction, Mereen-Johnson ensures your production line runs smoothly, maximizing profitability and reducing downtime.

A double end tenoner allows you to process both ends of a material simultaneously, doubling production output while maintaining precision and joint quality.

Our single end tenoners are designed to handle both large production runs and smaller, more customized orders, offering flexibility for diverse batch sizes.

The servo-driven alignment system ensures that the material is securely positioned during cutting, providing high precision regardless of the size of the production run.

Mereen-Johnson’s tenoners are designed to process wood, composites, and other green resources, making them versatile for a wide range of production environments.

Yes, both our single and double end tenoners are equipped with intuitive touchscreen controls that are easy for operators to learn, reducing training time and boosting productivity.