612-529-7791 or 1-888-4MJSAWS

5301 East River Road, Suite 113, Minneapolis, MN 55421

Email Mereen-Johnson

Leading Technology – Lasting Performance

It’s Only Natural To Want The Best.

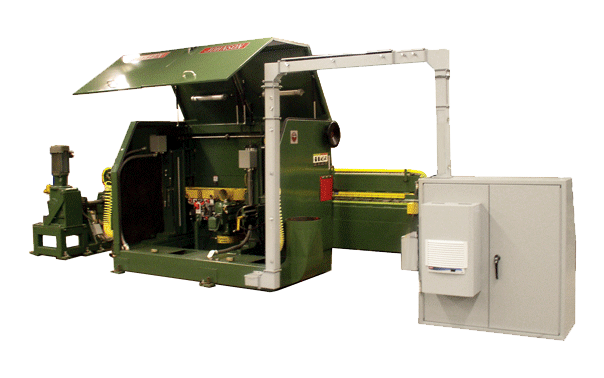

MEREEN-JOHNSON goes to extremes when it comes to accuracy – cutting wood, composites, plastic, concrete, aluminum & more.

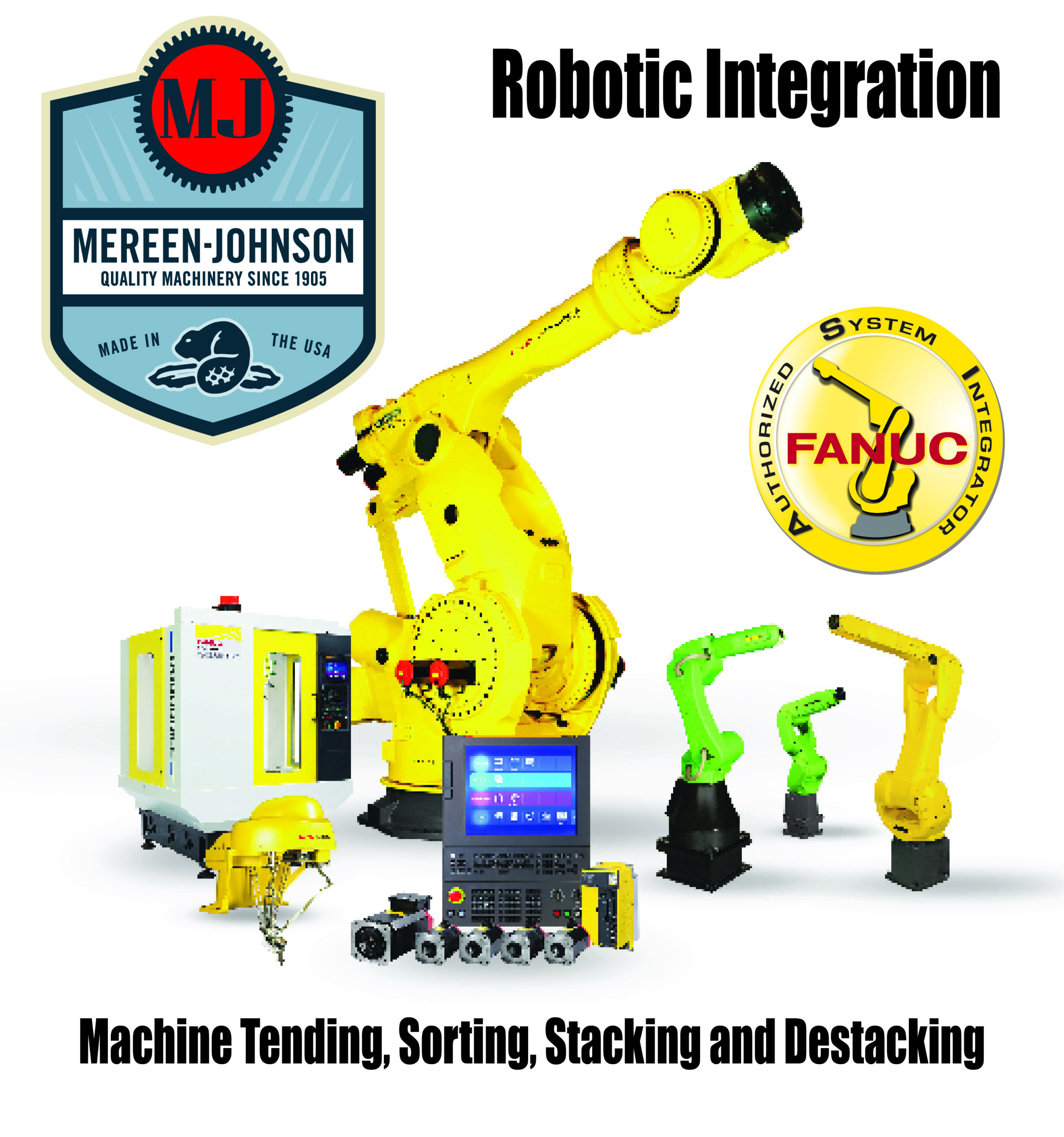

Click HERE learn more about how robotics can Be a Game Changer for Your Business or request a no-obligation FREE Lunch & Learn.

Modern-Day Machinery & Material

In today’s world, conservation & replenishable resources have become a part of our nature.

Whether it’s ensuring the highest yield possible or embracing the use of composite materials, MEREEN-JOHNSON customers have come to depend upon the durable longevity and accuracy of our machinery.

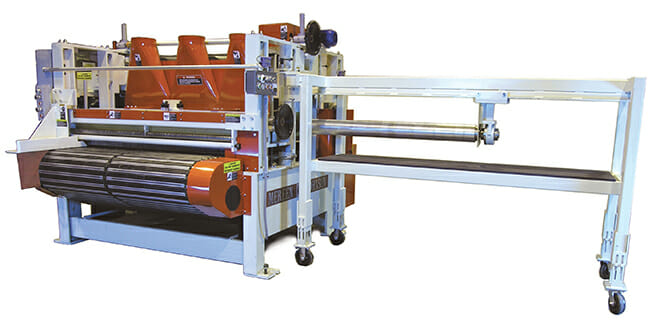

Rip Saws

Optimizing Systems

Dovetailers

Tenoners

Sizing Machines

Some of Our Industry Leading—Cutting Edge Equipment

- Moving Blade Gang Rip Saws

- High Speed Roll Feed Rip Saws

- Tenoners

- Panel Sizing Systems

- Box Presses

- I-Joists & Other Structural Wood

Equipment

- Fixed-Arbor Rip Saws

- High Production Run Dovetailers & Box Presses

- Door Sizing Systems

- High-Pressure Laminate Trim Lines

- Material Handling

- Automation

- Robotics

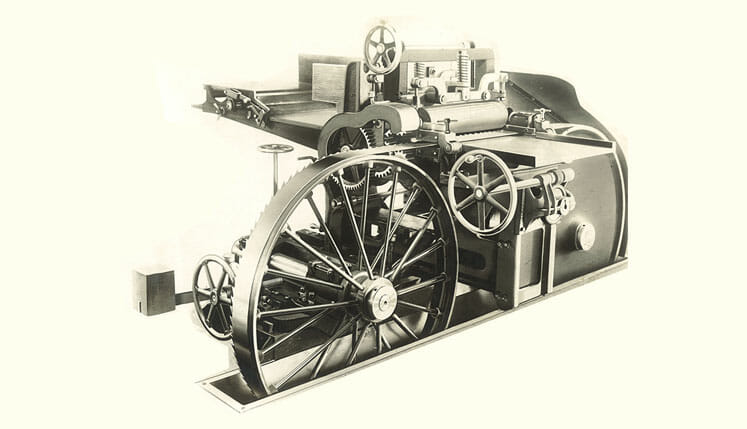

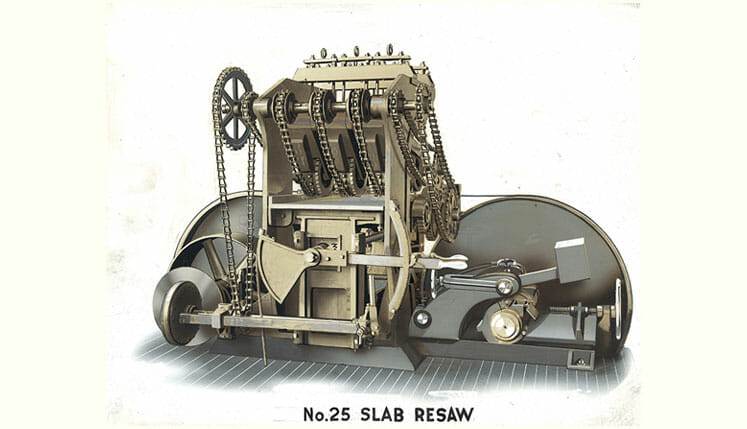

Leaders Of Precision Since 1905

MEREEN-JOHNSON’s technically advanced methods complement our complete line of the rip saw optimizing systems.

Our history of performance since 1905 has guided the precision that’s built into each of our high-performance, lowest cost of ownership machines.

At Mereen-Johnson, our customers trust that we support the environment through our state-of-the-art yield management systems. Each machine provides technically advanced, cutting edge solutions that deliver the most eco-friendly production available on the market today.

More About Us

Our Vision

We are positioned to address the challenges that woodworking manufacturing operations will face in the future; just as we did back in 1905. Although manufacturing methods have changed since then, it is our goal to produce only the finest quality products & services has not.

Our Value

Quality products that are manufactured in the USA, Mereen-Johnson provides assurance to the original purchaser that the equipment will be free from manufacturing defects with a industry leading warranty. Want to continue that great feeling a warranty provides? We got you covered.

Our Team

Our engineers & robotic integrators use the latest technology, manufacturing facilities, employing state-of-the-art CNC machining centers, & internal quality controls to ensure performance precisely as designed. We also offer expert level of support to keep your equipment running at peak efficiency.

Reach Out To Our Team

MJ Main

Our Location

5301 East River Road

Suite 113

Minneapolis, MN 55421

Map & Directions

Contact Information

Phone: 612-529-7791 or (1-888-4MJSAWS)

Fax: 612-529-0120

Follow Mereen-Johnson

© 2024 Mereen-Johnson. All Rights Reserved. Diehl Machines is a subsidiary.