612-529-7791 or 1-888-4MJSAWS

5301 East River Road, Suite 113, Minneapolis, MN 55421

Email Mereen-Johnson

Shifting Blade Rip Saws

Maximize Efficiency

Performance & Quality When You Need It

As is true with all Mereen-Johnson machines, our full line-up of Shifting Blade Rip Saws provides unprecedented yield management, maximizing raw materials, minimizing waste, and getting you the parts you need when you need them.

Our proprietary moving blade system offers one moving blade in combination with a gang-sleeve to six fully-shifting blades with edge hogging capacity. Customers have come to trust that these machine deliver the performance desired and quality demanded.

Model 524-DC/SR

Select Ripping Has Never Been More Affordable

With up to four moving saw blades, selective ripping has never been more affordable. Moreover, now a NEW two arbor version of the Model 524 is available, arranged to edge lumber on first arbor & precision rip on the second arbor. To learning more click HERE.

Model 524-DC/SR 2+4

Higher Profits, With Greater Operator Safety

This 2-arbor saw represents the ultimate in production flexibility featuring a first arbor equipped with two shifting blades to virtually eliminate edge strips and a second arbor with up to four shifting blades. To learning more click HERE.

Reach Out To Our Team

MJ Main

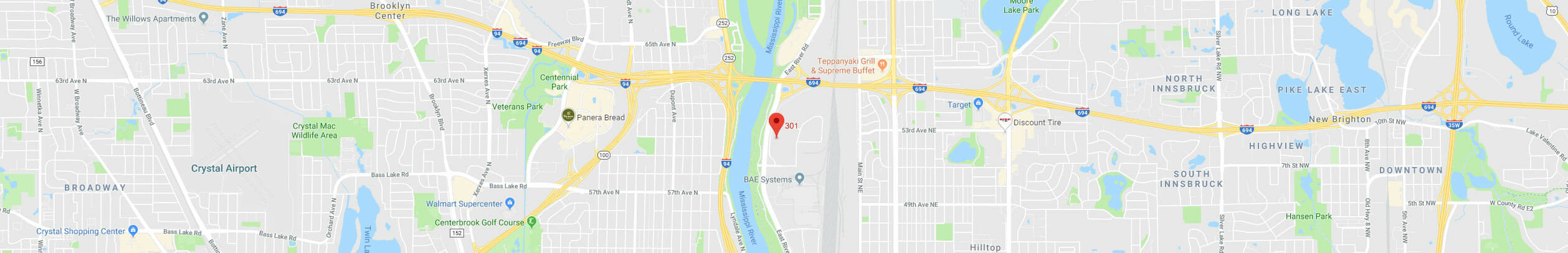

Our Location

5301 East River Road

Suite 113

Minneapolis, MN 55421

Map & Directions

Contact Information

Phone: 612-529-7791 or (1-888-4MJSAWS)

Fax: 612-529-0120

Follow Mereen-Johnson

© 2024 Mereen-Johnson. All Rights Reserved. Diehl Machines is a subsidiary.